Your Complete Guide to SCADA Training (Course List Included)

SCADA is a cornerstone technology within Industrial Automation, widely utilized across industries and government infrastructure for monitoring and controlling critical assets.

As global industries advance and pursue digital transformation, the development of shop floor automation and SCADA systems has accelerated, increasing both their capabilities and applications.

Modern SCADA systems now encompass a diverse array of functions with some platforms evolving to incorporate Manufacturing Execution System (MES) roles.

With the evolution of SCADA technology, the need for advanced skills and workforce upskilling has grown. Modern SCADA platforms offer a wide array of functionalities, enabling end-users to obtain highly customized automation solutions that are individualized for their facility.

However, successful deployment relies on acquiring the necessary knowledge and training.

Who Needs SCADA Training?

Training is important for all individuals working within the supply chain of SCADA systems. Training is essential for end users and engineering contractors to manage the delivery of SCADA builds, upgrades, and modifications effectively.

Fundamental knowledge of SCADA systems enables end-users to;

- Establish a SCADA basis of design for their facility

- Define project requirements and design constraints

- Manage compliance issues and deviations, technical queries and punch closure

For integrators and field engineers, hands-on technical, platform-specific SCADA training enables the configuration and application development tasks necessary to configure and build SCADA systems in line with clients’ requirements.

End-User and EPC Contractors

Establishing Project Specifications

Those working as end-users or engineering contractors are typically responsible for defining project specifications and the basis of design. Initial SCADA design serves as a foundation for the evolution of detailed engineering to be carried out by integrators and automation suppliers.

This involves creating a set of engineering drawings, documents, lists, and schematics. This initial design acts as a reference for suppliers and subcontractors, allowing the chosen integrator to develop the final detailed design.

This process may include developing a general high-level system architecture, identifying all major interfaces and subsystems, and defining the project’s normative references, applicable standards, and other design guides and constraints.

These individuals must possess the skills, knowledge and experience to effectively define and communicate design requirements to suppliers.

Initial design may include design elements such as:

- The number and placement of operator clients and workstations

- Rough tag count estimations and partially defined I/O list

- Sketches of level 1 and level 2 HMI graphics

- Prefered Media transmission types for different network legs

- A list of Devices, subsystems and packages requiring SCADA integration

- Interfaces with none automation systems such as ERP, MES

- Requirements for data logging and the historisation of process variables

- Any custom logic or scripting to be implemented within the SCADA

- Specifications for hosting the SCADA server, whether offsite, onsite, or in the cloud

- Requirements for SCADA network redundancy, availability, manageability and scalability

- Specific end-user requirements for cyber security

Overseeing SCADA Delivery

Engineers and managers who oversee the delivery of major SCADA projects, whether as end-users or engineering contractors, must ensure that every aspect of the delivered design aligns with all contractual requirements and project specifications.

These roles demand a solid understanding of SCADA system design in order to provide effective oversight, validate the final design, and ensure compliance with regulations and project specifications.

It is also their responsibility to safeguard their organization’s interests by ensuring adherence to the agreed-upon design and preventing suppliers from intentionally over-engineering or over-specifying the design, which could lead to inflated costs.

These oversight activities may include:

- Reviewing and commenting on SCADA engineering deliverables from suppliers

- Attending and witnessing testing, such as FAT, SAT, and other formal inspections of panels, network components, control rooms ect.

- Checking and ensuring compliance with regional and internal standards

- Oversee punch closure and coordinate the acceptance and handover to facility operations teams

SCADA Integrators and Engineers

Developing SCADA Detailed Design

System integrators (SIs) are responsible for advancing the SCADA design from its initial concepts to a fully developed, detailed design. This phase requires specifying all elements in detail, enabling the development and construction teams to move forward with software configuration and panel fabrication.

This process of taking the design from basic to detailed involves specifying details that go beyond the capabilities of end-users and EPC contractors, such as;

- Specifying Media Converters and Gateways: Identifying appropriate media converters and gateway technologies along with their settings to ensure seamless communication across the network.

- Optimizing IP Addressing and Subnetting: Designing an efficient IP addressing scheme and subnetting plan tailored to anticipated network loads and requirements.

- Creating SCADA Templates and Classes: Designing templates and classes within the SCADA system to enable bulk development of common control stratagies.

- Custom Scripting: Developing scripts and routines to implement custom reports, HMI interfaces, batch recipes ect.

Building the System – Technical Skills

Engineers working with integrators or suppliers responsible for delivering a SCADA project must be capable of configuring the system to realize the detailed design that has been commercially agreed upon. Examples of such configuration activities may include:

- Configuring devices and interfaces in line with interface specifications

- Developing HMI graphics in accordance with P&IDs

- Configuring tags, templates, and classes in line with agreed I/O schedules

- Scripting for enhanced user interfaces, process automation, and data handling

- Configuring databases for historians, alarms, and events

- Configuration of switches, firewalls, and media converters

SCADA Training Overview

The SCADA training curriculum should be tailored to align with the responsibilities and scope of the trainee’s role, considering their specific job function, organization, and position within the supply chain. Generally.

SCADA training courses can be categorized into three main types:

- Knowledge and System Design

- SCADA Platform Configuration

- Supporting Applications

Foundational Knowledge (General SCADA Training)

These high-level courses provide fundamental concepts and principles for designing and managing SCADA systems. They cover topics such as network architecture, transmission media, and hosting, which are essential for developing project specifications for contractors and suppliers.

Configuration (Technical Integration Skills)

Platform Configuration training focuses on the installation and configuration of specific SCADA platforms. It is technical and hands-on, emphasizing device integration, tag and template management, licencing, and HMI development.

Skills for Supporting Applications

Beyond the SCADA platform configuration, specialized courses cover topics such as OPC Client Management, Advanced Scripting for HMI, Industrial Networks, and Cybersecurity.

SCADA Training Providers

When looking for a SCADA training provider, you have several options, each with varying price points, scope, depth, quality, and delivery modalities.

Training from SCADA Platform Developers

SCADA platform developers offer structured training courses, which may be free or paid. These courses are often scheduled at the supplier’s training locations or can be arranged onsite upon client request.

These courses equip trainees with skills to perform configuration tasks on the supplier’s platform.

Additionally, some suppliers provide free access to extensive “How-to Guides,” which are useful resources for working with their products.

Licensed Training Providers

Some suppliers license their training content to third parties, who then schedule and conduct these courses at their facilities. The cost of these courses is typically similar to those offered directly by the supplier.

The advantage of licenced providers is their wider geographical reach, allowing for more flexible locations. Virtual classrooms provide more options for different time zones. Many licensed training providers are also fully-fledged automation contracting firms, and their trainers may offer more significant insights and practical experience beyond the standard course content.

Independent Training Providers

Independent training providers are those not affiliated with any SCADA platform developer. If you are funding your own SCADA training, you will find many affordable options from these providers. They offer online courses in both on-demand and scheduled formats.

The cost of training can vary greatly and is often proportional to the depth and quality of the training. Unfortunately, there is a large presence of low-quality training providers, some of which rely heavily on AI-generated material, and whose instructors may lack industry experience.

Choosing a SCADA Training Provider

Automation JobSearch has conducted research on affordable online SCADA training providers in the USA, Canada, UK, and Europe, offering various formats such as remote self-paced, virtual classroom, and live classroom training.

Our team has compiled a list of SCADA training courses ranging from budget-friendly e-learning options to more comprehensive multi-day virtual classroom courses.

This list is designed to assist you in choosing the most suitable SCADA training course for yourself or your employees to advance your professional development.

General SCADA Training Courses

These general courses are designed for management, operators, and end-users responsible for overseeing SCADA integrations but are not necessarily involved in detailed configuration tasks.

These programs focus on key design and delivery principles, equipping participants with the knowledge to manage SCADA integration projects, navigate the tendering process, or provide project oversight at a managerial level.

Based on our research, we recommend the following general SCADA training courses:

- SCADA System Integration by ISA

- SCADA Training by The Knowledge Academy

- SCADA Basics: From Fundamentals to Practical Applications by Realpars

SCADA System Integration (IC30M) by ISA

Course Details

| Course Provider | International Society of Automation (ISA) |

| Course Title | SCADA System Integration (IC30M) |

| Course Delivery | On-demand |

| Cost | 815 USD |

Learning Outcomes

- Understand the evolution of SCADA from its original technologies.

- Identify what distinguishes SCADA from other process control systems.

- Apply various SCADA system architectures.

- Determine which process control parameters SCADA systems can or cannot manage.

- Analyze key components and their integration within a SCADA system.

- Apply communication protocol rules for machine-to-machine interactions.

- Select appropriate protocols based on field-specific requirements.

- Calculate scan times for different system sizes.

- Differentiate the pros and cons of different communication media used in SCADA.

- Describe the benefits and drawbacks of data interoperability standards.

- Explain SCADA applications in oil and gas production.

- Describe the role of SCADA in electric generation, transmission, and distribution.

- Identify SCADA applications in irrigation and municipal water treatment.

- Discuss future trends and drivers for SCADA applications.

SCADA Training by The Knowledge Academy

Course Details

| Course Provider | The Knowledge Academy |

| Course Title | SCADA Training |

| Course Delivery | Scheduled Virtual Classroom |

| Cost | 1295 USD |

Learning Outcomes

- Understand the basic principles and components of SCADA systems.

- Configure and troubleshoot SCADA networks for optimal performance.

- Analyze real-world case studies to gain practical insights.

- Ensure the security and reliability of SCADA systems.

- Familiarize yourself with industry best practices and standards.

- Implement strategies for efficient data collection and control.

- Apply SCADA knowledge across different sectors, from manufacturing to utilities.

SCADA Basics: From Fundamentals to Practical Applications by RealPars

Course Details

| Course Provider | RealPars |

| Course Title | SCADA Basics: From Fundamentals to Practical Applications |

| Course Delivery | On Demand |

| Cost | Subscription Model: 25 EUR / Month |

Learning Outcomes

- Understand the basic principles and components of SCADA systems.

- Configure and troubleshoot SCADA networks for optimal performance.

- Analyze real-world case studies to gain practical insights.

- Ensure the security and reliability of SCADA systems.

- Familiarize yourself with industry best practices and standards.

- Implement strategies for efficient data collection and control.

- Apply SCADA knowledge across different sectors, from manufacturing to utilities.

SCADA Configuration Training Courses

These configuration training courses focus on the installation and setup of specific SCADA platforms. They are technical and hands-on, with an emphasis on device connectivity, tag and template management, licensing, and HMI development.

Ignition SCADA

Ignition SCADA by Inductive Automation® provides an unlimited licensing model, instant web-based deployment, and a comprehensive toolset within a single, open, and scalable platform.

Marketed as “The New SCADA,” Ignition aims to tackle the significant challenges posed by traditional SCADA systems, which often involve multiple disparate applications, by offering a fully integrated, highly scalable web-based solution.

Inductive University – Credentials Course

Inductive University is a free online training platform offering comprehensive resources to help trainees master the Ignition SCADA platform.

Course Details

| Course Provider | Inductive Automation |

| Course Title | Credential Courses |

| Course Delivery | On Demand |

| Simulation Environment | Free Trial* |

| Course Duration | 1 Week |

| Cost | Free |

*Note: Ignition offers a fully functional trial version that can be used indefinitely. The trial runs in 2-hour increments, after which it can be restarted to continue testing without any limitations. This allows you to explore all features, including design, development, and testing, without a license.

Learning Outcomes

- Getting Started with Ignition: Understand platform basics and different editions.

- Ignition Gateway Setup: Configure the Gateway, connect OPC UA and devices, and manage databases.

- Launching Ignition: Use Ignition Designer to manage clients and sessions.

- Tags in Ignition: Tag creation, utilize Tag Historian, and set up alarming.

- Visualization with Ignition: Design Vision Windows, work with Vision components and bindings, and build Perspective pages, views, and containers.

- Platform Skills: Develop scripting, manage SQL databases, ensure security, and localize Ignition.

- Historical Data Handling: Manage transaction groups and generate reports.

- Enterprise Features: Implement the Enterprise Administration Module for multi-site management.

- Logic Charts: Create and use Sequential Function Charts (SFC) for process automation.

Plant SCADA (AVEVA)

|

|

Plant SCADA was originally developed by Citect, a company with roots dating back to the 1970s when it began developing control systems for mining operations. In the early 1990s, Citect SCADA was launched and quickly gained popularity within the broader domain of industrial automation and process control. In 2006, Schneider Electric acquired Citect and rebranded the software as Plant SCADA.

The story took another turn in 2018, when Schneider Electric merged its industrial software business with AVEVA, a UK-based leader in engineering and industrial software. Today, AVEVA develops and supports Plant SCADA as part of its extensive portfolio, continuing to enhance the software’s capabilities and driving digital transformation.

SCADA Programming for Industry by Scantime

Founded in 2004 and based in the UK, Scantime Engineering Ltd has pioneered online e-learning courses for PLC and SCADA systems.

Course Details

| Course Provider | Scantime |

| Course Title | SCADA Programming for Industry |

| Course Delivery | On Demand |

| Simulation Environment | Remote access to CitectSCADA* and Simulator |

| Cost | 140 USD |

*Note: CitectSCADA is an early version of what is now known as PlantSCADA. While it has been rebranded, the training and core concepts remain applicable for those interested in learning and working with AVEVA Plant SCADA.

Learning Outcomes

- Understand the fundamentals of SCADA, including its purpose and role in industry.

- Differentiate between SCADA and HMI systems and their respective functionalities.

- Learn about Industrial PCs (IPCs) and their use in SCADA systems.

- Gain knowledge of key SCADA suppliers and industry terminology.

- Install and run CitectSCADA, setting up and navigating through the software.

- Develop practical skills by creating and managing SCADA projects, including templates, pages, and navigation elements.

- Configure SCADA systems, including user management, communication setup, and project compilation.

- Master SCADA tag addressing and design considerations for robust system architecture.

- Advanced features include date, time, 3D elements, and industrial objects.

- Utilize Genies for efficient tag management and SCADA project configuration.

- Learn to backup, restore, and prepare SCADA projects for client deployment.

- Connect SCADA systems to PLCs, managing communications and port configurations for effective process control.

AVEVA Plant SCADA (formerly Citect) Configuration – by SolutionsPT

SolutionsPT is an industrial engineering consultancy that offers software, hardware, and services to manufacturing and infrastructure organizations across the United Kingdom and Ireland.

In addition to engineering services, they provide a wide range of training programs for SCADA and industrial IT applications.

Course Details

| Course Provider | SolutionsPT |

| Course Title | AVEVA Plant SCADA (formerly Citect) Configuration |

| Course Delivery | Scheduled Virtual Classroom |

| Simulation Environment | None specified |

| Course Duration | 3 days |

| Cost | 3100 USD |

Learning Outcomes

- Create Projects: Develop new projects using the Situational Awareness Starter Project.

- I/O Communication: Use Plant SCADA to interface with I/O devices.

- Equipment Hierarchy: Implement and benefit from an equipment hierarchy.

- Graphics Development: Design and modify graphics pages and symbols.

- Alarm and Trend Management: Generate, manage, and configure alarms, trends, and reports.

- Troubleshooting: Identify and resolve issues encountered during the course.

- Online Resources: Effectively use Plant SCADA Help Topics and Knowledge Base.

Learning Academy (elearning) – by AVEVA

AVEVA Learning Academy features an e-learning section with a comprehensive collection of on-demand video guides for configuring the Plant SCADA platform. These free videos are available to integrators and end-users working with AVEVA products.

Although the content is not organized into a formal course structure, it provides a valuable resource for learning essential configuration aspects.

| Course Provider | AVEVA Learning Academy |

| Course Title | AVEVA™ Plant SCADA 2023 and Citect SCADA 2018 R2 |

| Course Delivery | On demand Video Modules (unstructured content) |

| Simulation Environment | N/A |

| Cost | Free Access for End-Users* |

*If you are an end-user or integrator working with licensed AVEVA software, you can request access.

Learning Outcomes

AVEVA™ Plant SCADA 2023 Cicode Fundamentals:

- Understand variables and data types in Cicode.

- Implement logic and statements within Cicode.

- Utilize arguments and return functions in Cicode.

- Configure input and output operations in Cicode.

- Develop skills using the Cicode Development Environment.

- Gain an introduction to Cicode programming.

- Master Cicode functions and their applications.

Citect SCADA 2018 R2 Configuration and Programming:

- Define a topology and manage project configurations.

- Associate faceplates with equipment and enable navigation.

- Configure and manage alarms, and add library objects to pages.

- Prepare equipment definitions and create situational awareness projects.

- Design and manage graphics pages, content pages, and system models.

- Implement operator input, menu configuration, and process analyst tools.

- Work with genies, composite genies, and report configurations.

- Configure security and manage alarms, devices, and events.

- Understand interlocks and workspace management.

inTouch (AVEVA)

InTouch SCADA was developed by Wonderware in the early 1990s. It gained popularity for its intuitive graphical interface and real-time data capabilities.

In 1999, Wonderware was acquired by Invensys, which expanded InTouch SCADA’s features and reach. Schneider Electric acquired Invensys in 2014, integrating InTouch SCADA into its range of industrial software solutions.

In 2018, Schneider Electric merged its industrial software business with AVEVA, a UK-based engineering software provider. Today, AVEVA continues to develop and support InTouch SCADA, maintaining its enduring role in industrial automation.

AVEVA InTouch HMI Training – by SolutionsPT

Course Details

| Course Provider | SolutionsPT |

| Course Title | AVEVA InTouch HMI Training |

| Course Delivery | Scheduled Virtual Classroom |

| Simulation Environment | Not Stated |

| Course Duration | 3 days |

| Cost | 3850 USD |

Learning Outcomes

- Create and manage InTouch applications: Learn to build stand-alone applications, export/import tags, configure and test navigation, and distribute applications to production environments.

- Tag and data management: Understand how to create, monitor, and manage tags, including I/O configuration, DBDump/DBLoad utilities, and historical data logging.

- HMI design and visualization: Build HMIs using Situational Awareness symbols, custom symbols, and Key Performance Indicators. Visualize and interact with real-time and historical data.

- Alarms and events management: Configure InTouch alarms, manage live and historical alarms, and understand advanced alarm features such as inhibition and suppression.

- Security configuration: Implement OS security, lock down applications, and use scripts to manage access and security settings.

- Scripting and automation: Gain proficiency in QuickScript and ArchestrA Symbol QuickScript .NET for automating tasks and enhancing application functionality.

- Web client usage: Learn how to set up and use the Web Client for runtime operations, including configuring windows for web access.

- Application maintenance: Back up and restore applications, manage Industrial Graphics, and convert windows for web use.

Step-by-Step Learn Wonderware InTouch – by Udemy

Udemy is the most budget-friendly InTouch course on our list. Among the many SCADA InTouch courses available on Udemy, we selected one that stands out for offering well-structured content and a large volume of positive reviews.

Course Details

| Course Provider | Udemy / Goeduhub Technologies |

| Course Title | AVEVA InTouch HMI Training |

| Course Delivery | On Demand |

| Simulation Environment | Demo Application Provided |

| Cost | 20 USD |

Learning Outcome

- Understand SCADA Systems: Gain a comprehensive understanding of SCADA systems, including their purpose and how they are used in industrial processes.

- Master Wonderware InTouch: Learn how to effectively use Wonderware InTouch SCADA software to create and manage control systems for various industrial applications.

- Develop SCADA Interfaces: Acquire the skills to design and implement SCADA interfaces using animation links, including features such as touch links, color fills, object movement, and visibility controls.

- Write SCADA Scripts: Learn how to write and implement scripts within the SCADA system to automate processes and enhance system functionality.

- Implement Real-Time Trends: Understand how to monitor and analyze real-time data trends within the SCADA system to improve operational efficiency.

- Set Up Alarm Systems: Gain the ability to configure and manage alarm systems within SCADA to monitor critical conditions and respond to system alerts.

- Manage Recipes in SCADA: Learn how to implement recipe management systems within SCADA for consistent and efficient process control.

- Enhance SCADA Security: Understand the methods to implement security measures within the SCADA system to protect against unauthorized access and ensure data integrity.

- Interface SCADA with PLCs: Develop the skills to interface SCADA systems with PLCs and other industrial controllers, ensuring seamless communication and control.

- Use DDE Protocol: Learn how to implement and use Dynamic Data Exchange (DDE) protocols for data exchange between SCADA and other applications.

- Apply Knowledge in Real-World Projects: Gain practical experience by applying your knowledge to SCADA-based projects, reinforcing the concepts learned throughout the course.

WinCC (Siemens)

WinCC SCADA, developed by Siemens in the mid-1990s, was created to provide solutions for industrial automation and process control. It became known for its flexibility, visualization capabilities, and easy integration other Siemens’ automation products.

In 1999, Siemens integrated WinCC SCADA with their SIMATIC automation platform, adding more functionality and positioning it as a key part of their industrial automation offerings.

Over the years, Siemens introduced new features to WinCC, such as advanced scripting, web-based monitoring, and data logging.

SCADA Tutorials using Siemens automation WinCC – by Bin95

BIN95 Industrial Training has been a cornerstone in automation and industrial training since the 1990s. The company has consistently provided high-quality training to engineers and technicians long before the widespread availability of industrial automation learning resources.

Despite its old-school website appearance, which harks back to the early days of the internet, BIN95 remains a trusted resource for professionals seeking in-depth, practical knowledge in automation.

Their commitment to quality training has helped countless engineers advance their skills and careers, solidifying BIN95’s reputation as a leader in the field, even as the training industry has rapidly expanded around it.

Course Details

The SCADA course is provided as a 73-slide PowerPoint with instructor notes, along with an 86-question online test. It offers a cost-effective alternative to online SCADA courses, priced at just a fraction of the cost.

Students can complete the course at their own pace and on their own schedule, as all materials require a one-time download. The course content is accessible offline, with the only online component being the final SCADA test.

| Course Provider | Business Industrial Network (BIN95) |

| Course Title | SCADA tutorials using Siemens automation WinCC |

| Course Delivery | On Demand |

| Simulation Environment | Not Stated |

| Cost | 199 USD |

Learning Outcome

- Understand SCADA Fundamentals: Learners will be able to explain the basic principles of SCADA systems and identify key features of WinCC.

- Create and Configure WinCC Projects: Participants will be capable of setting up a new project in WinCC on a standalone PC and configuring essential components such as tags, alarms, and graphics.

- Simulate PLC Connections: Students will demonstrate proficiency in creating connections between WinCC and a PLC using the S7-PLCSIM simulator.

- Design and Customize Graphics in WinCC: Learners will develop skills in using the Graphics Designer tool in WinCC to create and customize visual elements for monitoring and controlling processes.

- Configure and Display Alarms: Students will gain the ability to configure alarms within a SCADA system and display them effectively for real-time monitoring.

- Enhance Industrial Network Security Awareness: Participants will acquire knowledge on industrial network security practices relevant to SCADA systems.

- Apply Knowledge in Real-World Scenarios: Learners will complete hands-on tasks using real SCADA software, reinforcing theoretical knowledge through practical application.

- Assess Understanding Through Tests and Challenges: Students will engage in multiple assessments and challenges to validate their understanding of SCADA concepts and tools.

WinCC MADE EASY: Program Siemens HMIs by Building Real World Applications – by RealPars

Based in the Neatherlands, RealPars is a leading online learning platform that specializes in industrial automation training, particularly for engineers and technicians.

Founded to address the gap in practical, accessible automation education, RealPars has built a strong reputation by offering concise, high-quality training on topics such as PLC programming, industrial networks, and control systems.

Course Details

| Course Provider | RealPars |

| Course Title | WinCC MADE EASY: Program Siemens HMIs by Building Real World Applications |

| Course Delivery | On Demand |

| Simulation Environment | Student should install TIA Portal Basic V16 or higher to follow course content. |

| Cost | Subscription Model: 25 EUR / Month |

Learning Outcomes

- HMI Configuration: Understand HMI concepts and configure HMI devices in TIA Portal.

- PLC Integration: Integrate PLC programs with HMI screens for effective interaction.

- Screen Development: Design and develop HMI screens using WinCC.

- Compilation and Simulation: Compile and simulate HMI screens to validate functionality.

- Element Management: Manage and customize HMI element properties.

- Navigation Systems: Create and implement navigation systems across multiple HMI screens.

- Testing and Simulation: Simulate and test multi-screen navigation strategies.

- Object Configuration: Configure additional objects and animations using WinCC.

- Project Finalization: Finalize and test HMI projects through simulation.

SCADA in Action: From Architecture to Applications Course Overview – by Koenig

Koenig Solutions is a global IT training provider known for offering a wide range of certification courses and specialized training programs. Established in 1993, Koenig has grown into a leader in the education sector, providing in-depth technical training for IT professionals across various industries.

Course Details

| Course Provider | Koenig Pvt. Ltd. |

| Course Title | SCADA in Action: From Architecture to Applications Course Overview |

| Course Delivery | Scheduled Virtual Classroom |

| Simulation Environment | Students should install TIA Portal Basic V16 or higher to follow course content. |

| Cost | 1450 USD |

Learning Outcomes

- Understand the role and functionality of SCADA systems within industrial environments.

- Identify and describe key components of SCADA architecture and their interactions.

- Learn data acquisition methods and communication protocols specific to SCADA systems.

- Gain the ability to create and configure a SCADA project from scratch.

- Establish communication connections and configure runtime settings for devices within a SCADA network.

- Design and configure graphic views, text displays, and alarms for effective monitoring and control.

- Implement data logging and trend analysis to monitor and optimize system performance.

- Develop proficiency in managing recipes within SCADA systems for process control and batch operations.

- Understand and configure user administration to secure access to the SCADA system and maintain regulatory compliance.

- Apply learned concepts through practical exercises, reinforcing the ability to manage and troubleshoot SCADA systems.

Siemens WinCC Professional SCADA – by Udemy

Course Details

| Course Provider | Udemy / Megha Kumari |

| Course Title | Siemens WinCC Professional SCADA – by Udemy |

| Course Delivery | On Demand |

| Simulation Environment | Students should install TIA Portal Basic V16 or higher to follow course content. |

| Cost | 20 USD |

Learning Outcomes

- Understand the role and functionality of SCADA systems within industrial environments.

- Identify and describe key components of SCADA architecture and their interactions.

- Learn data acquisition methods and communication protocols specific to SCADA systems.

- Gain the ability to create and configure a SCADA project from scratch.

- Establish communication connections and configure runtime settings for devices within a SCADA network.

- Design and configure graphic views, text displays, and alarms for effective monitoring and control.

- Implement data logging and trend analysis to monitor and optimize system performance.

- Develop proficiency in managing recipes within SCADA systems for process control and batch operations.

- Understand and configure user administration to secure access to the SCADA system and maintain regulatory compliance.

- Apply learned concepts through practical exercises, reinforcing the ability to manage and troubleshoot SCADA systems.

iFIX (GE)

GE iFIX SCADA, originally developed as part of GE Automation’s suite of industrial control solutions, has played a significant role in the evolution of automation technology. Initially, iFIX SCADA focused on providing reliable, real-time control and monitoring for industrial systems across industries like manufacturing, utilities, and energy. Its user-friendly interface and robust functionality made it a popular choice for supervisory control and data acquisition (SCADA) systems.

In 2015, GE launched GE Digital, marking a strategic shift towards the Industrial Internet of Things (IIoT) and digital transformation. GE iFIX SCADA became part of a broader ecosystem, integrating with digital platforms like Predix, GE’s IIoT platform. This integration expanded iFIX’s capabilities beyond traditional SCADA, allowing it to harness the power of data analytics, cloud computing, and predictive maintenance, enhancing industrial operations in a more connected and data-driven world.

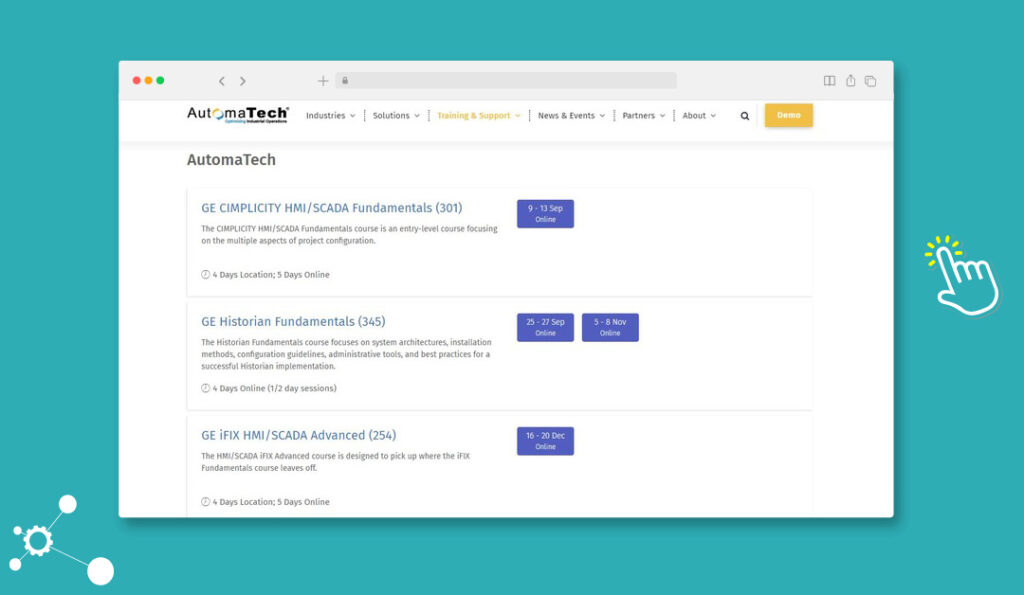

GE iFIX HMI/SCADA Fundamentals – by AutomaTech

Automatech provides industrial automation training through both in-person and virtual classroom options. Training centers are located in Billerica, Massachusetts, and Nashua, New Hampshire, offering hands-on courses in SCADA systems, PLC programming, and more.

Automatic offers two courses for iFIX; a fundamentals course and an advanced course.

Course Details

| Course Provider | AutomaTech |

| Course Title | GE iFIX HMI/SCADA Fundamentals |

| Course Delivery | Scheduled Virtual Classroom and onsite |

| Simulation Environment | Students should have access to iFIX installation to follow course content. |

| Course Duration | 5 days |

| Cost | 2495 USD |

Learning Outcomes

- Understand communication: Establish and manage communication between iFIX SCADA Servers and iClient nodes.

- Node configuration: Set up and configure iFIX nodes using the System Configuration Utility.

- Driver and OPC setup: Set up I/O Drivers and OPC Servers for effective communication with iFIX.

- Database tags: Create and modify Process Database tags for better data handling.

- Graphic screen development: Design and create graphic screens (pictures) using various object types and animations.

- Navigation strategy: Develop a coherent picture navigation strategy within the system.

- Basic scripting: Write basic scripts using Visual Basic for Applications (VBA).

- Alarm configuration: Configure alarms and design screens for alarm monitoring.

- Data trending: Utilize trending tools to monitor both real-time and historical data effectively.

- Security design: Develop a comprehensive security strategy across the system.

- Troubleshooting: Utilize various iFIX Utilities and OS tools for troubleshooting project or system issues.

GE iFIX HMI/SCADA Advanced (254) – by Graymatter

GrayMatter, based in Pittsburgh, Pennsylvania, is a privately owned company specializing in industrial automation, data intelligence, and operational technology solutions.

They provide in-depth training programs that focus on SCADA systems, cybersecurity, and industrial analytics, offering hands-on workshops and expert-led sessions.

Course Details

| Course Provider | GrayMatter |

| Course Title | GE iFIX HMI/SCADA Advanced (254) |

| Course Delivery | Scheduled Virtual Classroom and onsite |

| Simulation Environment | Students should have access to iFIX installation to follow course content. |

| Course Duration | 5 days |

| Cost | 2495 USD |

Learning Outcomes

- Architecture Review: Understand and review the iFIX architecture and its applications.

- Project Maintenance: Perform effective maintenance of iFIX projects.

- OPC Integration: Integrate and utilize OPC DA, UA, and AE within the iFIX environment.

- Asset Model Development: Develop and expand asset models within iFIX.

- Advanced Database Blocks: Dive deeper into the configuration and use of database blocks.

- Server Failover: Configure enhanced failover capabilities for iFIX servers.

- Relational Database Integration: Integrate iFIX with various relational databases.

- Graphical Tools: Use VisiconX to create graphical relational database tools for user interaction.

- Historian Integration: Connect iFIX with Proficy Historian for data storage and retrieval.

- Alarm Systems Extension: Expand iFIX alarm system functionality with relational databases and Proficy Historian.

- ActiveX and .NET Integration: Extend iFIX capabilities using ActiveX controls and .NET integration.

- Dynamo Management: Master the creation and maintenance of Dynamo objects.

- Scheduling: Configure and manage iFIX schedules effectively.

- Security Implementation: Implement advanced security measures within iFIX.

- Thin Client Solution: Explore and utilize the iFIX thin client solution for remote access.

iFIX Fundamentals online course – by Novotek UK

Novotek is a European leader in industrial automation and digital transformation, specializing in delivering solutions for industries such as manufacturing, energy, and infrastructure. Founded in 1986 and headquartered in Sweden, Novotek has expanded its presence across several countries, including Denmark, Finland, and the Netherlands.

The company provides comprehensive training programs, focusing on SCADA, PLCs, MES, and other automation technologies, helping professionals enhance their skills in implementing and managing advanced industrial systems. Novotek is known for its close partnerships with industry leaders like GE Digital and ABB.

Course Details

| Course Provider | Novotek UK |

| Course Title | iFIX Fundamentals online course |

| Course Delivery | Scheduled Virtual Classroom |

| Simulation Environment | Students should have access to iFIX installation to follow course content. |

| Course Duration | 5 days |

| Cost | 1290 GBP |

Learning Outcomes

- iFIX Architecture: Understand the communication framework between iFIX SCADA Servers and iClient nodes.

- Node Configuration: Configure iFIX nodes using the System Configuration Utility for networking, tasks, and alarm services.

- I/O Drivers & OPC Integration: Set up I/O Drivers and OPC Servers to interface with iFIX systems.

- Process Database Management: Create and modify Process Database tags, including both digital and analogue types.

- Graphic Design: Develop graphic screens using a range of object types, animations, and data-entry controls.

- Navigation Strategy: Design and implement picture navigation strategies for user-friendly interfaces.

- Scripting: Create basic scripts using Visual Basic for Applications (VBA) to extend functionality.

- Alarming & Monitoring: Configure alarms and design displays for alarm monitoring.

- Data Trending: Implement trending to visualize real-time and historical data.

- Security Design: Develop a robust, system-wide security strategy.

- Troubleshooting: Utilize various iFIX utilities and operating system tools for diagnosing and resolving system issues.

VTSCADA

VTScada, developed by Trihedral Engineering, has been a steady presence in the SCADA (Supervisory Control and Data Acquisition) software landscape since its release in 1986. Known for its reliability and flexibility, VTScada is widely used in sectors like water management, oil and gas, and energy distribution.

Its integrated approach, combining features such as alarms, trends, and historians within a single platform, simplifies the deployment of SCADA systems by reducing the need for third-party tools.

VTSCADA Software Training – by Trihedral

VTScada Academy (On Demand)

The VTScada Academy offers free online training designed to help you learn VTScada or advance your application development skills.

VTScada Scheduled Training Courses

Trihedral offers paid training courses both online and at their Florida and Texas locations. These three-day courses are priced at $1,000 USD each and are available at two levels:

- Level I – Operation & Configuration

- Level II – Advanced Configuration

Learning Outcomes (Level 1)

In this course, VTScada operators and developers will build comprehensive VTScada applications from start to finish.

- Introduction to VTScada

Overview of VTScada features, concepts, and basic application management tools. - Tag Management

Using the Tag Browser to add, configure, and create tag hierarchies. Communication with hardware, including ports, drivers, and I/O tag configuration, as well as best practices for tag creation. - Application Design

Tools for drawing, editing, and formatting objects using the VTScada Idea Studio. Creating and configuring display pages, setting up page navigation, adding and configuring labels, and widgets for tag values. - Advanced Configuration

Time-saving techniques, including exporting tags, utilizing the Tag Links Panel, and developing custom widgets. Securing applications with accounts, roles, and privileges. Creating and managing alarms and using the Alarm Notification System. - Data Management and Reporting

Configuring data logging with the Historian, using the Historical Data Viewer, generating reports, building expressions with the Calculation tag, and setting up the application for multiple workstations with primary and backup servers. - System Integration and Version Control

Configuring the VTScada Internet Server, connecting via thin clients, and using the Version Control System to manage changes. Additional topics may be covered based on time and student interest.

Learning Outcomes (Level 2)

- VTScada Features and Configuration: Review of VTScada features, configuration properties for appearance and functionality, and workstation-specific settings. Advanced expression programming for enhancing tags and widgets.

- Context Tags and Customization: Detailed exploration of context tags, sites, and connectors. Creating complex multi-tag structures, custom widgets, and parameterized pages for reusable screens. Utilizing tabbed folders and enhancing the Tag List widget with custom widgets. Introduction to Smart Sites.

- Security and Reporting: Advanced security management and customization, including realm filtering and global tag & area filters. Advanced report generation techniques, such as controlling data collection, history editing/importing, using the Excel add-in, and configuring the ODBC interface for SQL queries of VTScada data.

- Application Protection and Version Control: Creating and using OEM layers for protecting or distributing custom tools. Understanding ChangeSets and VTScada version control.

- Diagnostics and Scripting: Manage subordinate applications and use VTScada utility applications for diagnostic purposes. Introduction to the VTScada scripting language.

VTSCADA YouTube Channel – by Trihedral

VTScada’s active YouTube channel offers a wealth of high-quality content, featuring over 200 tutorials. These videos cover a wide range of technical topics, including connectivity, troubleshooting, licensing, and more, providing valuable resources for both new and experienced users.

Automation JobSearch is run by automation engineers who are dedicated to advancing the field of industrial automation. We believe in the significant role of industrial automation in driving sustainability and economic growth.

We provide job listing products to support small and medium-sized automation companies and recruiters in their talent acquisition efforts, ensuring they find the right candidates quickly and efficiently. Our online job board attracts both active job seekers and passive candidates, providing exposure to a focused candidate pool of automation professionals.

Additionally, in line with our commitment to the industry, we actively promote graduate and intern positions at no cost, recognizing the critical need to attract more graduates to our profession.